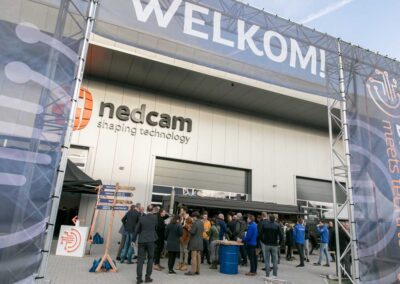

Nedcam – Shaping technology

Nedcam produces moulds, models, prototypes and complete products from various materials based on digital 2D and 3D designs with high-performance 5-axis CNC machines. Thanks to a total concept of advice, management, realization and innovation, Nedcam offers the right solution for every project.

Want to know what we can do for you?

Working with an open mind

Our markets

Nedcam produces plugs and moulds for the composites industry. Main markets are yacht building, wind industry and automotive. In addition, Nedcam provides sustainable concepts for construction and is known for its production of extreme 3D shapes from architecture. For this purpose, in-house facilities are used including high-quality CNC machines up to 26 meters in length. Nedcam also has a large 3D robot printer.

The latest news…

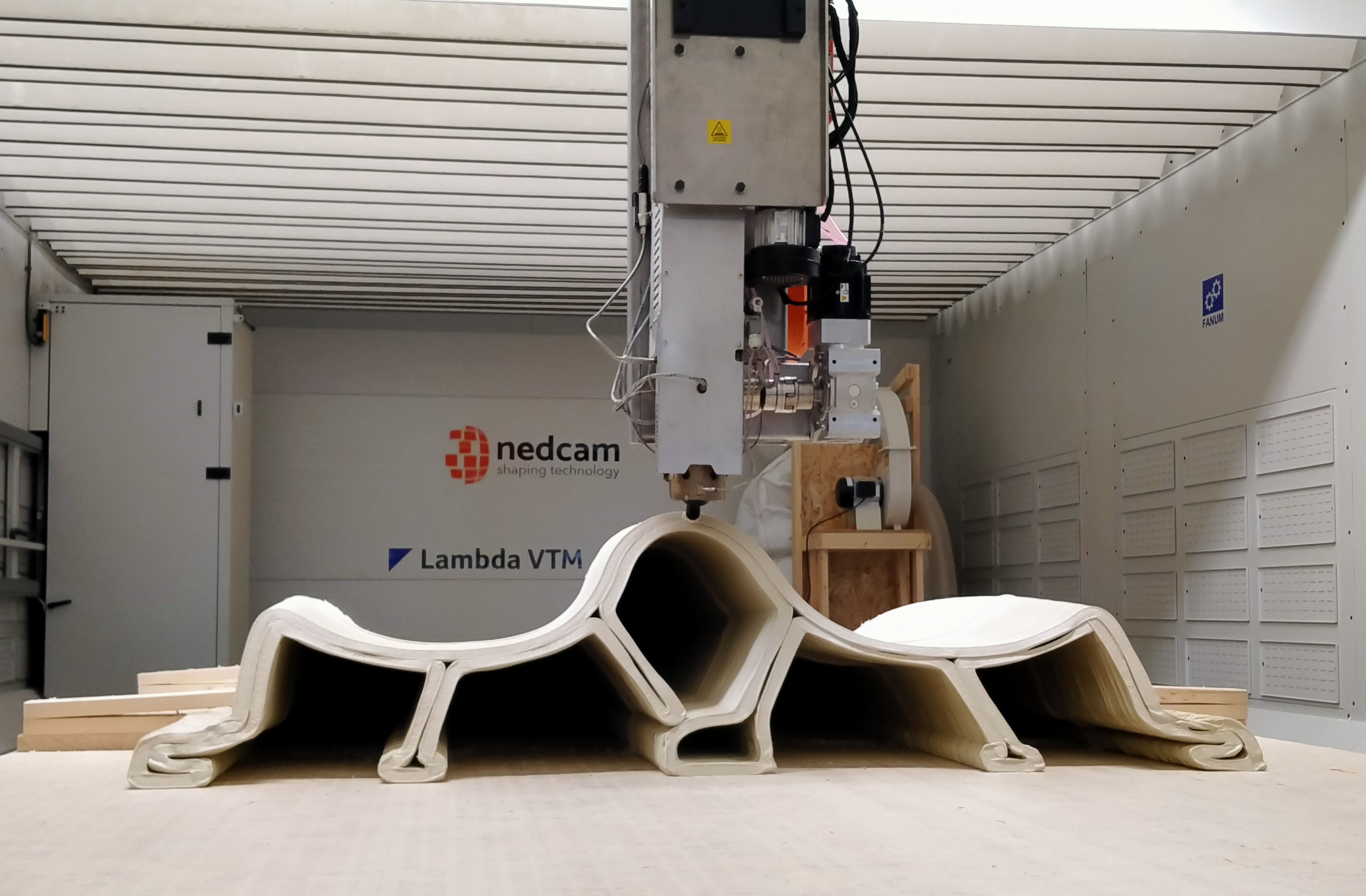

SUSTAINABLE PRODUCTION PROCESS

XXL 3D printer

A revolution in 3D printing in the composites industry. We would like to introduce you to our new 3D printer, the Fanum Lambda XXL 3D Printer, with a reach of 12 metres the leading 3D printer in Europe. From now on, we can print our moulds and thus make the traditional production process more sustainable.

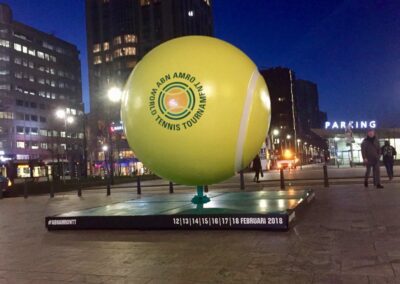

Nedcam Art&Architecture

'Out of the box', extreme and innovative. That's what architects and artists approach Nedcam...

Nedcam Yacht building

Nedcam has been a market leader in plugs and moulds in the yacht building industry for decades. For the whole of Europe, Nedcam builds composite plugs and moulds using CNC milling and 3D printing...

Nedcam Construction

In construction and infrastructure, increasingly complex works are desired by clients and architects. Nedcam has extensive experience in realising complex assignments...

Nedcam Automotive

Moulds and dies for the automotive industry are manufactured with high precision thanks to our high-quality and precise machinery...

Nedcam Wind

Nedcam has a very large capacity for making moulds for the nacelles, nose-cones and (parts of) rotor blades for the wind industry...

Forward-looking

With experienced and well-qualified staff and good facilities, Nedcam is ready for the future. Nedcam is driven by innovation and, together with its partners, is focused on looking ahead where “sustainability” is already a given.

Circular

With years of experience in the composites industry, Nedcam is now taking the next step to transform its own process from thermoset materials (GRP=Glassfibre Reinforce Plastic) to thermoplastic materials with the aim of being able to fully recycle them in the future

Sustainable

Not only is circularity high on the agenda. Nedcam strives to make all processes and products as sustainable as possible. Great example is working with a water-based composite; A1 = Acrylic One.

In addition, Nedcam is constantly working to minimize the footprint of its own facilities, as well as processes and materials with which it works